|

|

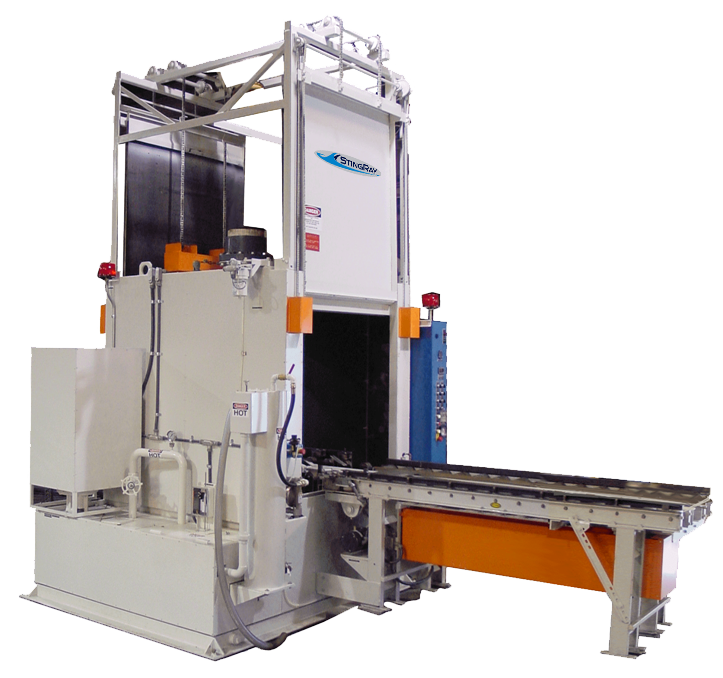

| Pump Upgrades |

Rinse System, Heated Fresh Water |

Automatic Rust Prevention System |

| StingRay pump system upgrades are available from the 20-horsepower Simplex up to the 140-horsepower Quadroplex. |

The StingRay fresh hot water rinse system provides a heated freshwater closed-loop rinse at the end of each wash cycle to remove the remaining detergent. |

The Rust-Inhibitor Protects parts from corrosion and flash rust with the injector system |

| Remote Grease Lubrication Points |

Automatic Lubrication System |

Hand Rinse Wand |

| The Remote Grease fittings on StingRay Aqueous Parts Washers simplify the necessary maintenance. |

The StingRay automatic lubrication system ensures critical bearings are properly lubricated on a regular basis. |

Enables manual rinsing of spot areas after a wash cycle. |

| Turntable Capacity |

Turntable Jog |

Hour Meter |

| Higher-rated capacities increase the work that can be performed in the parts washer. |

Convenient panel-mounted industrial control for easy rotation of the turntable during parts loading. |

Panel mounted hour meter maintains parts washer operating hours. |

| High-Low Pressure Switch |

Pump Amp Meter |

Stainless Steel Cabinet |

| The selectable output pressure of duplex-equipped pumping systems. |

Panel-mounted digital display tracks parts washer pump amp draw. |

All standard wetted components are stainless steel. |

| Pure Rinse: Reverse Osmosis Water System |

Adjustable Pressure Control |

Vacuum Dryer |

| Provides SPOT-FREE rinse via a Reverse Osmosis membrane system that removes hard water minerals. |

The StingRay AC variable speed drive provides optimum motor speed and torque control for energy-efficient wash pressure and flow control. |

Efficient Method to remove moisture with reduced pressures resulting in faster drying. |

| SmartWash Touchscreen |

Dual Door Upgrade |

Robotic Integration |

| SmartWash Touchscreen is an upgraded operator interface designed to revolutionize how you manage your cleaning. |

Dual Door Upgrade, you can load and unload parts on one side of the washer while the other side is actively engaged in the wash cycle. |

Designed to enhance operational efficiency by automating key functions and reducing labor. |

|

|

| Automatic Steam Exhaust System |

Center Manifold Probe |

Short High-Impact Manifold |

| Eliminates steam from your StingRay parts washer with the Automatic Steam Exhaust (ASE) System. |

Washes and rinses hollow diameter parts where the interior is not readily accessible to standard spray manifold arms. |

Two machines in one. A standard manifold for larger parts, and a shorter, ultra-high impact manifold for smaller parts washing. |

| Hot-Air Blow-Off |

High Speed Evaporation Drying |

Pump Pressure Regulator |

| The Hot Air Blow Off (HABO) system speed dries parts. |

Speeds flash drying of parts at lower cost than Hot Air Blow Off with near equal results. |

The Pump Pressure Regulator allows the operator to adjust the pressure discharge from the wash nozzles. |

| 50 Hz Operation |

World Model |

Heat Source - Gas, Electric, Steam |

| Provides the necessary changes to the parts washer to operate with the identical performance parameters as 60 Hertz. |

Parts washers for worldwide use. International Freight, Crating & VCI wrap. |

Choice of heating systems to fit your plant's energy source. |

|

|

| Oil Skimmer |

Sludge Scraper |

In-Line Filtration |

| The Oil Skimmer removes surface waste oils floating on the cleaning solution surface. |

Removes sludge, rocks, sand, soil, and other solid wastes from the bottom of the parts washer reservoir. |

Filters all parts washer fluid before discharging through the wash nozzles. |

| Oil Coalescing System |

Solution Transfer Pump |

Sludge Pump |

| Separates waste oil from parts washer cleaning solution. |

The StingRay Solution Transfer Pump is specially designed for transferring water-based liquids, fluids, and solutions from the parts washer. |

Ideal pump for handling all parts washer solutions and cleaning out your StingRay parts washer. |

| Wastewater Evaporator |

Magnetic Rod Particle Trap |

Solution Loop Filtration |

| Automated, efficient evaporation greatly reduces wastewater disposal costs. |

Removes particles in the single digit micron size, smaller than can be extracted by traditional filters. |

Designed to continuously filter the cleaning fluid in your washer's reservoir, keeping it clean. |

|

|

| Cabinet Noise Reduction Insulation |

Chemical Spill Containment Pan |

Industrial Control & Safety Disconnect |

| Reduces noise from the parts washer, while also providing thermal insulation. |

Secondary Containment, industry best practice for preventing reportable spill. |

Adds safety controls to the parts washer for employee protection. |

| Pump Sound Barrier |

Internal Reservoir Cover |

|

| Reduces noise from pump motor. |

Provides cover for solution in parts washer reservoir. Protects employees from hot wash solution. |

|

|

|

| Parts Washing Baskets |

Parts Washing Fixtures |

Tie-Down Ratchet Straps |

| Simplifies placing smaller items on the parts washer turntable for cleaning. |

Positions parts for optimum cleaning, improve rinsing, and provide drainage for best flash drying. |

A straightforward method of binding parts and baskets to the parts washer turntable for washing. |

| Parts Loading Jib Boom |

Turntable Anchoring Attachments |

Turntable Liner |

| Provides a convenient loading means mounted to the parts washer. |

Provides an uncomplicated way to attach and properly position wash loads on the parts washer turntable. |

Provides a stable and even surface for loading parts. |

| Pit Installation |

|

|

| Lowers the height of the turntable to shop floor level for ease of loading & unloading. |

|

|

|

|

| Thermal Insulation |

Internal Reservoir Cover |

Pump Size |

| Saves Energy, reduces pump noise, and lowers costs to heat machine. |

Increases Safety, conserves energy, and improves productivity. |

Properly sized pumps for the correct power density to wash soiled parts. Saves energy. |

| Steam Exhaust Damper |

|

|

| Volume control of steam exhaust saves energy and maximizes wash temperature. |

|

|