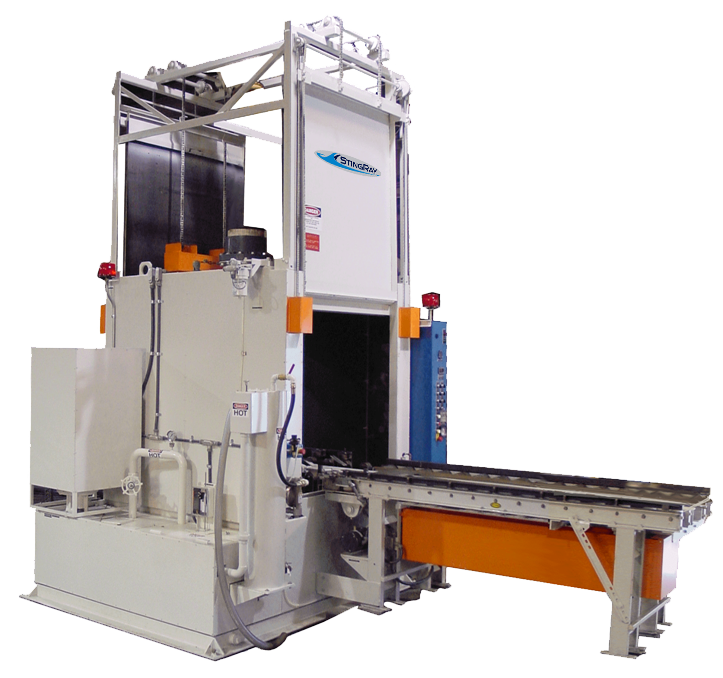

StingRay Automatic Steam Exhaust Damper

What this means is that the steam in your washer contains a tremendous amount of energy. Discharging the steam, dumps this heat into the sky and your machine heating system must make up for the loss. For energy conservation, keeping all the steam inside of the machine is best. However, steam wants to escape and having it dump into the plant is no good either. So, there is a happy medium between wasting heat out of the exhaust and having it spew into the plant. To achieve the ideal steam flow requires an adjustable system and the design of StingRay Steam exhaust damper fits this purpose exactly.

|

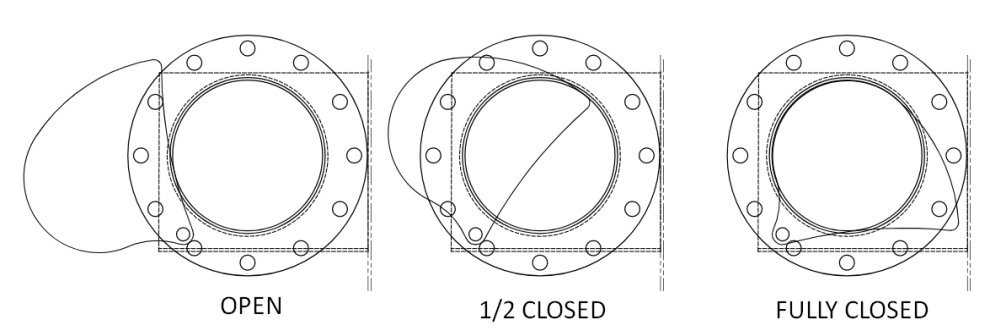

| Easily adjust the flow of steam during parts washing, from fully open to completely closed |

|

Field test results prove a 9 to 12 degree operating temperature increase from throttling of the steam discharge. The increase in temperature is HUGE. A 10-degree temperature rise almost doubles the chemical reactivity improving cleaning results. The cleaning improvement is permanent, requires no additional chemical, no more horsepower, no additional cleaning time and no additional heat. |

In situations where the current operating temperature delivers the desired cleaning results a damper saves energy. With a damper properly adjusted less steam discharges needlessly out of your building. Your heating system runs less and yet delivers the same cleaning results and the same operating temperature. The result is savings in the energy needed to heat the machine thus reducing operating cost.

Installation is simple: Drill one hole and install one bolt.

Kit includes: All stainless steel construction shutter damper and mounting fastener, installation template, and operating instructions. Available on all new StingRay or as a simple retrofit for all StingRay and MART Parts Washers.

Steam Exhaust Damper Advantages:

- Easily set the optimum amount of steam discharge.

- Increase operating temperature 9 to 12 degrees for Free

- Easy retrofit to all StingRay Machines.

- Easy to adjust - turn fully closed for tough soil removal and then change it back for normal washing

- Save money

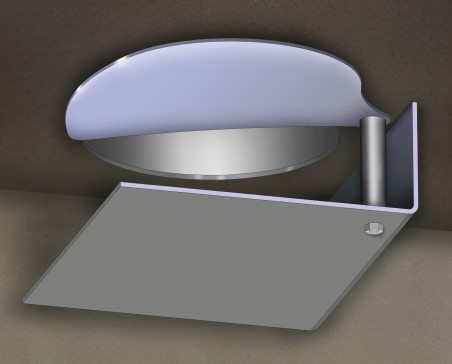

StingRay Steam Exhaust shutter style damper controls the flow of heat loss in the parts washer

|

A properly optimized steam exhaust saves energy and maximizes operating temperature leading to better cleaning results. |  |

| Exhaust damper fully closed | Shutter damper fully open |