StingRay Parts Washers

StingRay Industrial Parts Washer offers the world's premier aqueous washing technology. Every StingRay parts washing machine is carefully engineered with proven aqueous cleaning technology, and is built in the USA using industrial quality materials and components. Through many years of experience, StingRay parts washers evolved to contain the features of heavy duty part washers. Each washer is built with the reliability and the appropriate power density to get the job done in the toughest cleaning applications. StingRay provides a complete cleaning solution by offering various aqueous parts washers, cleaning detergent, spare parts and technical support to fit your parts cleaning needs. StingRay Industrial Parts Washers conserve water, reduce energy consumption, and do not pollute the environment. Thus, our environmentally friendly parts washers meet the goals of GREEN TECHNOLOGY cleaning solutions.

The StingRay Advantage

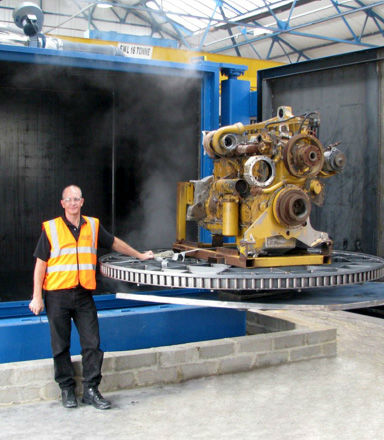

At the heart of every StingRay Aqueous Parts Washer lies the patented oscillating power blast manifold system that bombards wash loads with hot aqueous wash solution from a different angle each time the parts pass on the rotating turntable providing thousands of cleaning angles. This technology combined with our high-efficiency industrial pump systems, high power density, and high output heating systems delivers faster aqueous cleaning cycles and more thorough part cleaning. StingRay cleaning equipment is also environmentally safe with a closed-loop, zero discharge design to meet EPA and OSHA regulations.

Aqueous Parts Washer

There are many features of a StingRay Parts Washer including: An automatic aqueous cleaning cycle, enclosed steel aqueous washing cabinet, rotating turntable that retracts when the door is opened, patented oscillating manifold, aqueous solution level management, temperature controlled solution heating, pump suction filter, safety devices, and single point electrical system connection. Depending on your parts washing needs, StingRay Parts Washer optional features include: Stainless steel cabinet, heated fresh water rinse system, steam exhaust and blow-off systems. In addition to parts washer features, StingRay also offers a variety of Heavy Duty Parts Washer solution maintenance devices for heavy degreasing applications: Oil skimmer, Sludge scraper, Surface scraper, In-line filtration.

Handcrafted

Handcrafted