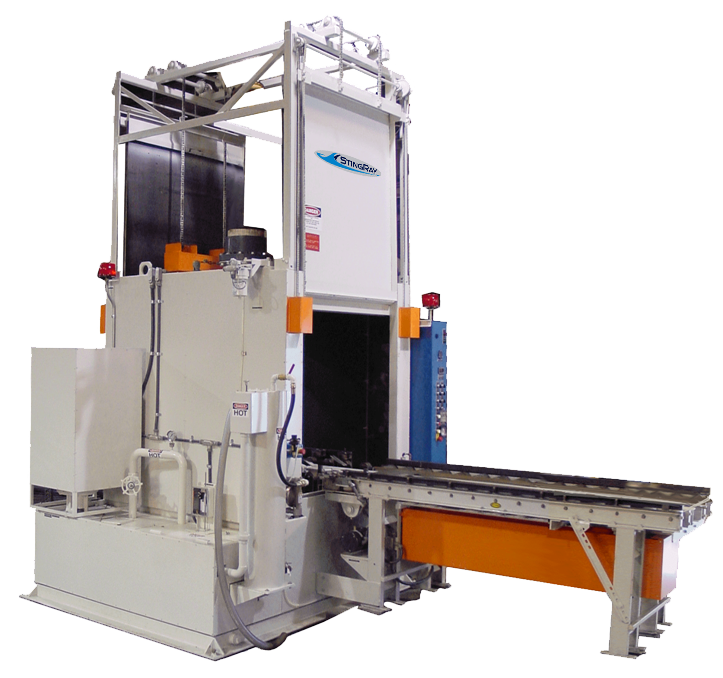

Designed for high performance and convenience

StingRay Eclipse ImmersoJet is a nozzle-mix combustion burner engineered for exceptional performance and

high reliability. The high velocity combustion gases from the burner scrub the inner heat exchanger tube

surfaces to produce the highest heat transfer rate of any immersion burner available. The ideal combination of

high velocity flow through a small diameter tube yields system efficiencies in excess of 80%

Benefits:

- Produces the industry’s highest heat capacities and

efficiencies. - Small Diameter Tube saves valuable reservoir space

making cleanout easier. - Easy installation with pre-mounted reliable high pressure

blower. - Pre-heat combustion air systems lowers burner surface

temperature and increases combustion efficiency. - Faster heat-up times than any other immersion burner.

- Combustion chamber is outside the reservoir, taking up

less space, providing uniform combustion and preheating

combustion air. - Unique air-fuel mix nozzle design ensures quiet operation.

- High pressure operation is unaffected by seasonal

atmospheric variances like commercial forced air burners.

Temperature, the flue exhaust pipe height and the total length of run including all elbows have the greatest

impact on natural draft in a flue. The draft will constantly change as a burner modulates, starts up or shuts

down. The draft is also affected by outdoor temperature, barometric pressure and wind, so a flue exhaust pipe

is not a very good draft controller. Draft variations due to fluctuations in outdoor air temperature alone can be

substantial. During the operation, the flue exhaust pipe will be “oversized” most of the time, which can lead to

inefficient and erratic operation. Changes in weather, barometric shifts or draft conditions caused by building

heating, ventilating and air conditioning may necessitate readjustment of the burner air/fuel settings. This

condition is virtually eliminated with the StingRay Eclipse Burner system because the burner has an extremely

powerful blower and fires at above atmospheric pressure to overcome draft changes. The StingRay Eclipse

firing pressure is 3 to 4 times higher than a standard commercial atmospheric burner.

For a gas burner heating a parts washer to be efficient and produce the lowest possible emission level, it must maintain a perfect flame and maximize heat transfer. A perfect flame can only be obtained by maintaining a precise fuel-to-air ratio with a proper air supply and proper draft. It is not uncommon to see high-efficiency burners operate at efficiency levels of low-efficiency burners. This is purely a result of lack of draft control

making the additional investment in high-efficiency wasted. The StingRay Eclipse Burner system utilizes a ratio regulator that varies the air-to-fuel ratio under varying atmospheric anomalies and firing conditions to maintain an optimum fuel to air ratio for maximum efficiency.

StingRay High Efficiency Burners Provides 80%+ Efficiencies

High Velocity Equals High Efficiency

Compare state-of-the-art ImmersoJet design with conventional immersion burners and tubes, ImmersoJet clearly comes out on top.

Equal Heat in Half the Area!

Compare the conventional heat exchanger tube with the ImmersoJet tube, each designed for 70% efficiency with an input of 1 MM Btu/hr. Clearly, the ImmersoJet style tube is much smaller. Lengthening the ImmersoJet tube and adding another pass achieves efficiencies in excess of 80%

Control System:

Design integrated into the StingRay Washer electrical control panel.

Offers numerous advantages:

- High Reliability Controls

- FM Rated Flame Control Module

- Industrial Dual Valves with positive actuation feedback to the controller

- Enclosure Disconnect provides safe access to internal components

StingRay Design Optimized Heat Exchanger:

In conventional immersion heating, every cubic inch of a tank is crammed with a bulky, large diameter tube. Replacing this tube with a compact smaller diameter tube in a serpentine shape provides substantial advantages:

In conventional immersion heating, every cubic inch of a tank is crammed with a bulky, large diameter tube. Replacing this tube with a compact smaller diameter tube in a serpentine shape provides substantial advantages:

- Reduced fuel costs

- Higher tank temperatures

- Conserved washer reservoir space.

Download details: PDF

StingRay Eclipse Combustion Burner System