Results of various electric motor components cleaning in StingRay Parts Washers. During start-up and commissioning of new StingRay machine installations the Service Technicians take photos of the parts washer in action to document the before and after results. Click on the photos for an enlarged view.

|

|

|

| Electric Motor Armature | Electric Motor End Bell | Electric Motor Armature |

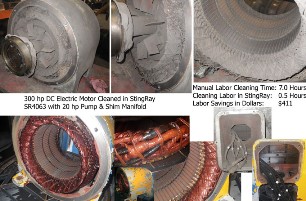

Traction Motor large photo cleaning results StingRay parts washer

Traction Motor washing: The stator, field windings, high temperature insulation, frame, bearings and rotor are all cleaned in the StingRay.

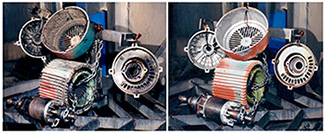

Large Photo: Before and after Electric motor stator cleaning results in a StingRay parts washer

An example of electric motor rebuilding for mining equipment showing aqueous washing of the stator, frame and windings with soap and water.

Electric motor washing results in StingRay aqueous parts washer

Example of aluminum end bell and fan cover plus stator

Before and After DC electric motor cleaning results in StingRay aqueous parts washer

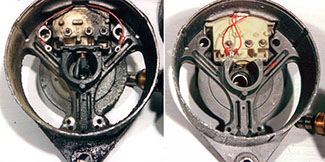

DC electric motor brush holder cleaning results StingRay industrial parts washer

All types of electric motors and components parts are cleaned with water and special low conductivity detergents. After washing, parts are rinsed with a heated fresh water and then dried.