NEWS Release: 6/20/2017

Shipped - StingRay Parts Washer #8606, SR4048RBW Parts Washer, Configured to Clean Remanufactured Rail Bearings for the Railroad Industry.

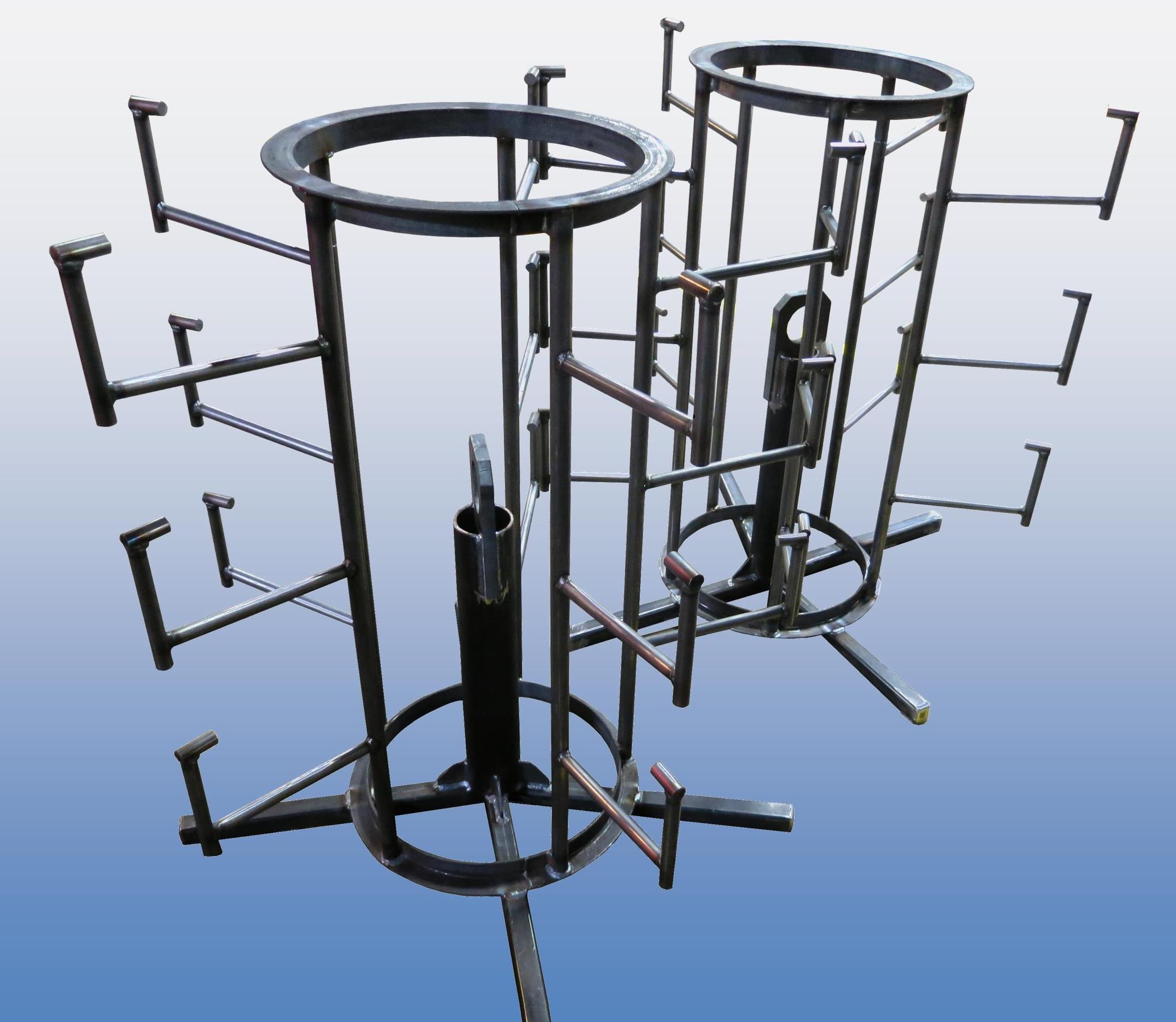

End User is a supplier of heavy haul equipment for the rail industry. With the opening of a new shop, a solution was needed for effective remanufactured rail bearings. End User opted for an upgraded 550,000 BTU gas burner and a high-flow short high-impact manifold to keep their cleaning temperatures high during each production day. With the help of two real bearing fixtures, this rail supplier will be producing many clean bearings for the next 20+ years.

Update on the User Results will be released once the Factory Service Technician completes the Start-up, Training and Commissioning , check back for results.

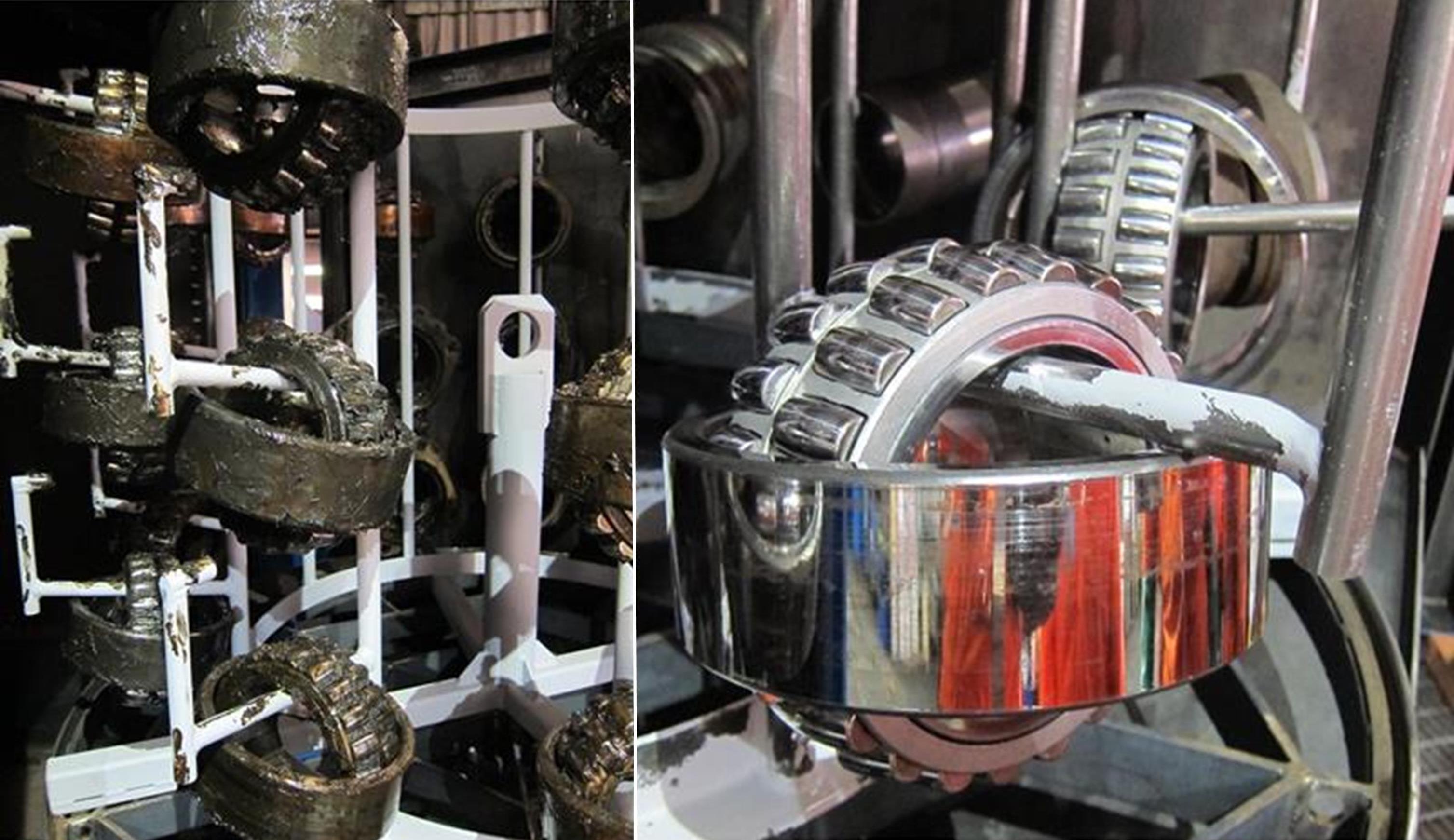

6/30/17 UPDATE: See User Results Below for New Photos from Start-up, Training and Commissioning!

Configuration Details:

| ♦ 40 hp Simplex Pump | ♦ Automatic Steam Exhaust | ♦ Remote Grease Fittings |

| ♦ 550 KBTU Gas Heat Source | ♦ Automatic Disc Oil Skimmer | ♦ Jib Boom with Trolley |

| ♦ Rail Bearing Fixtures | ♦ Internal Reservoir Cover (IRC) | ♦ Industrial Safety & Control Package |

| ♦ High-Flow Short High-Impact Manifold | ♦ Chip Basket for IRC | ♦ Rear Access Box for Easy Cleanout |

| ♦ Automatic Heated Fresh Water Rinse | ||

Click to Enlarge

**UPDATE** - START-UP, TRAINING AND COMMISSIONING AND CLEANING RESULTS

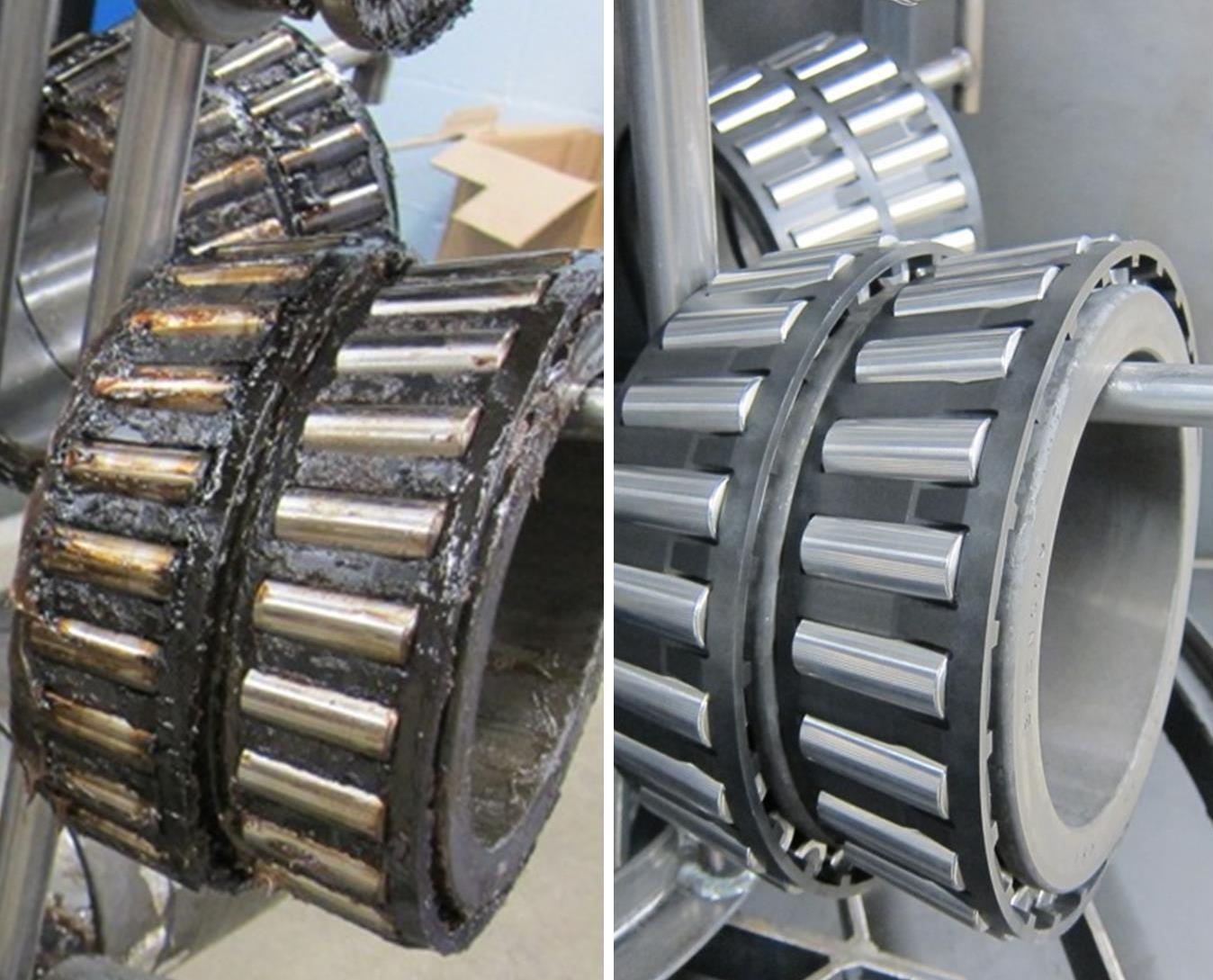

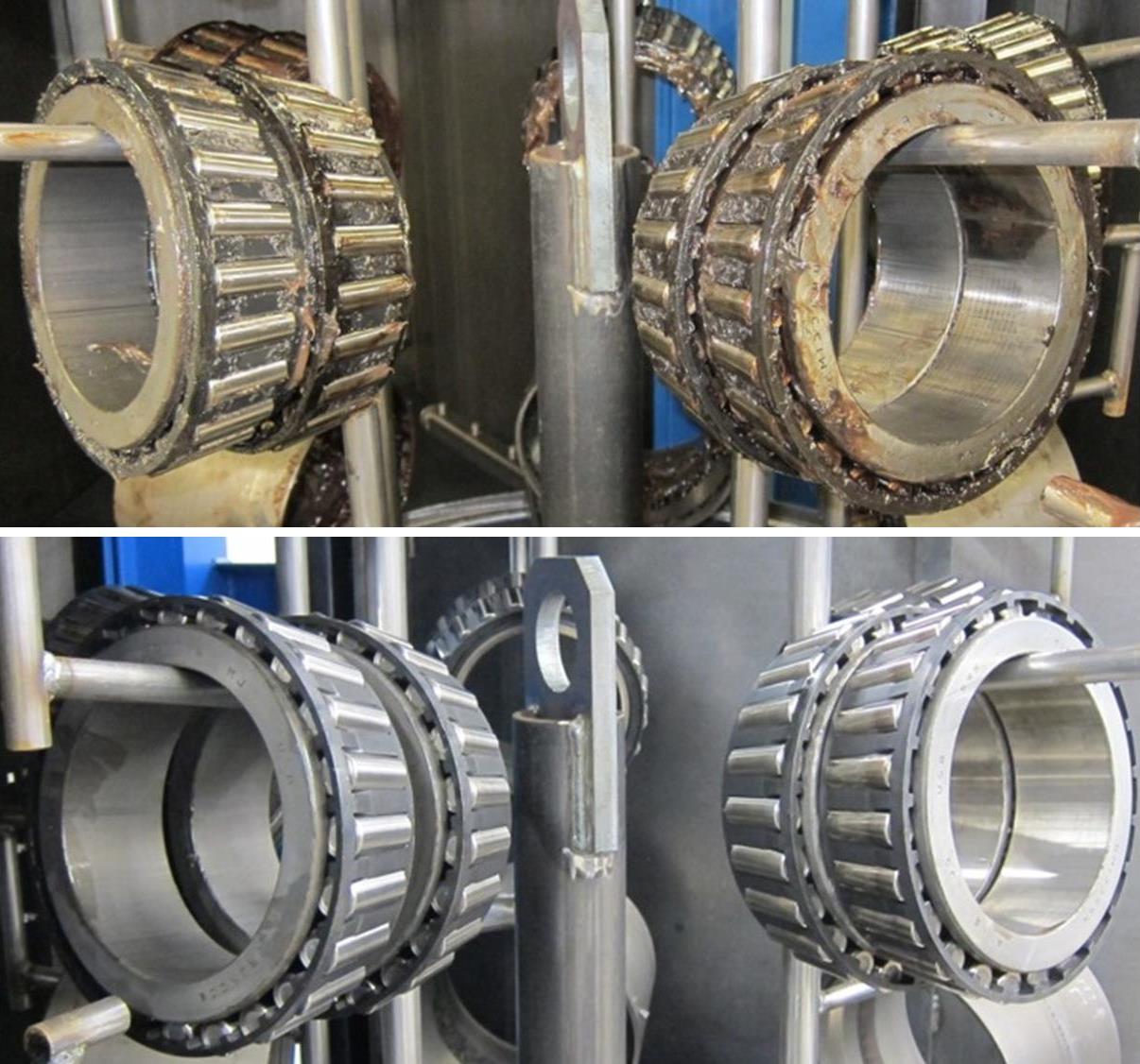

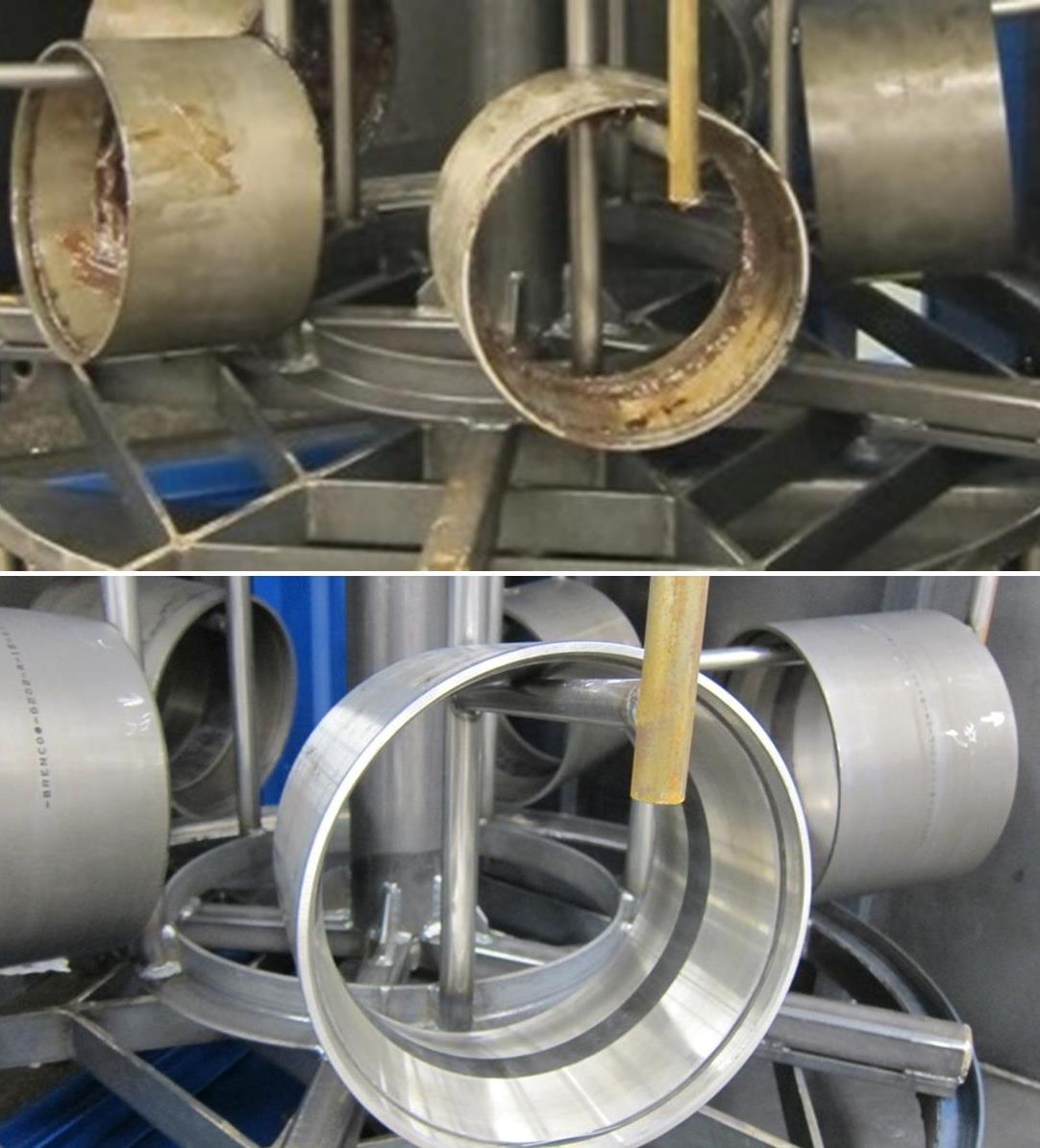

Short cleaning cycles produce totally clean rail bearings. Some users wash 1200 complete bearing assemblies in an 8n hour shift.

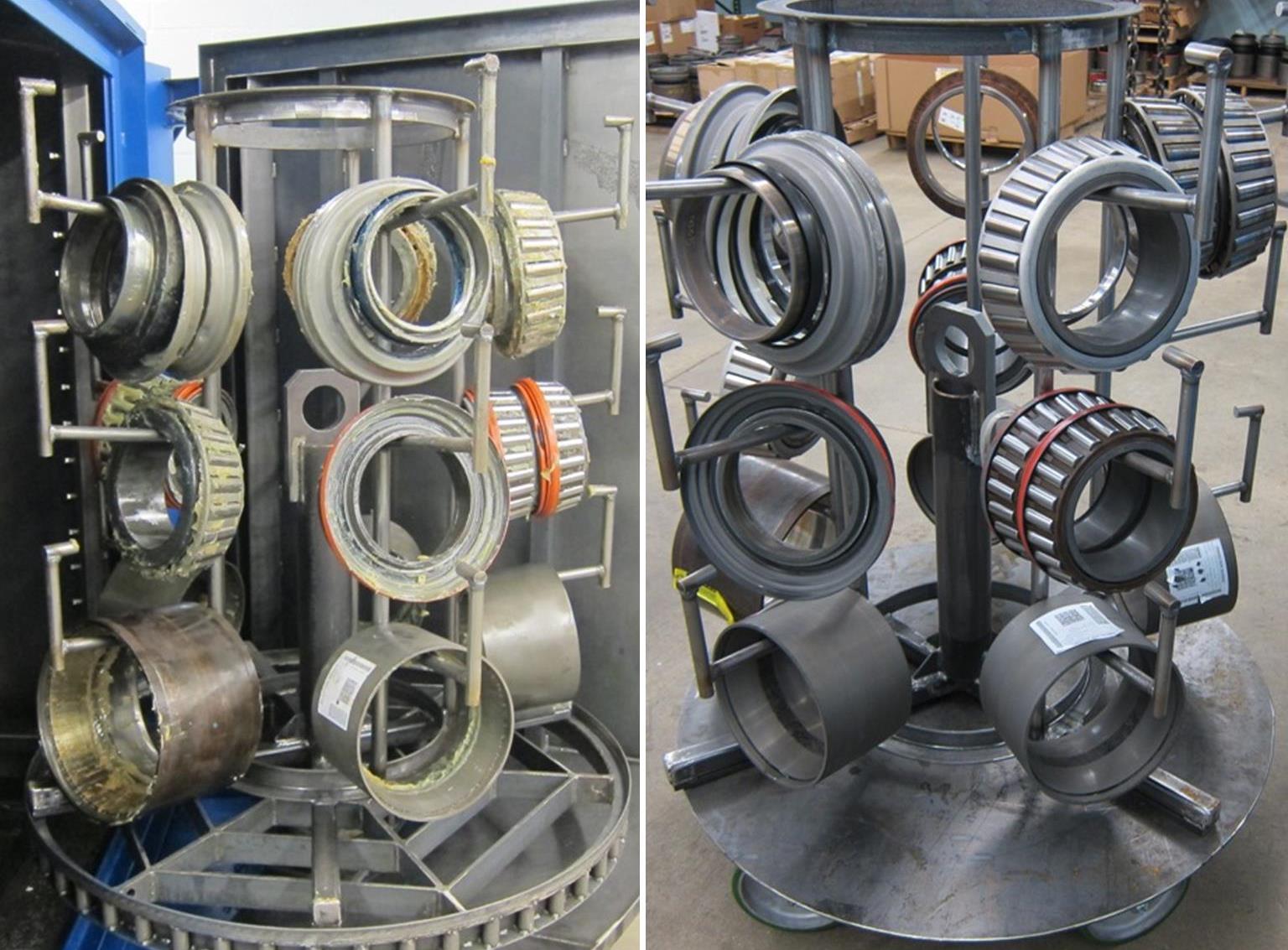

Cups, cones and rings all fit on the rail bearing fixtures. Parts for one bearing are stacked on three hooks vertically to keep them together during cleaning. Before and after cleaning results photos.

STINGRAY FABRICATION PHOTOS

rail spherical bearings clean just as well as tapered roller bearings on the StingRay fixtures.