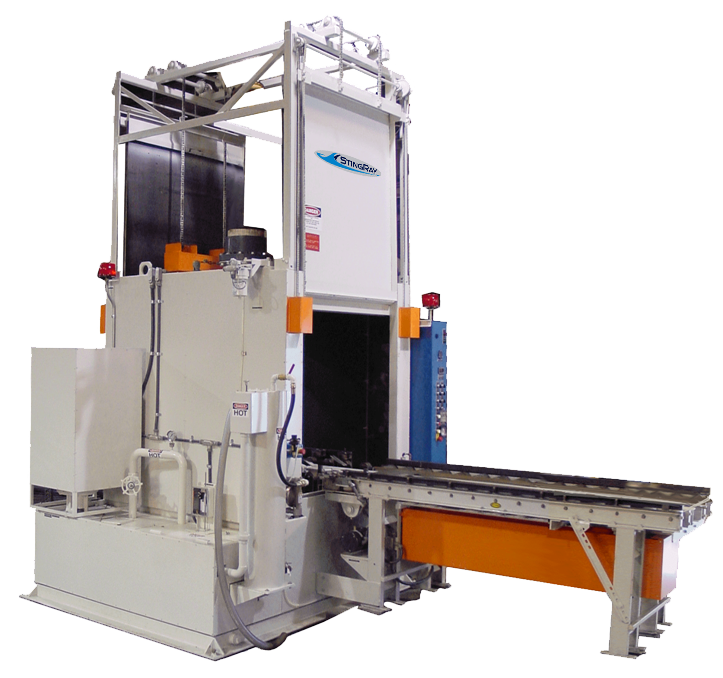

Retractable Turntable Heavy Duty Parts Washers

The StingRay 6075 parts washer not only offers an impressive parts washer power density for parts cleaning but also the patented oscillating power wash manifold to maximize parts cleaning in any industrial application. It is the ideal industrial parts washer for off-road and over the road truck engines and transmissions, mining equipment engines, and marine engines. Additional industrial parts washing applications include the repair and rebuilding of marine thrusters & propulsors, gears, crankcases, heads and pumps.

USA Specifications:

SR 6075 Parts WasherMetric Specifications:

SR 6075 Parts WasherStandard Features & General Construction:

- Green Technology: Closed Loop Zero Discharge

- Swing Door Retracting Turntable for Maximum Access

- Electronic Water Level Control & Refill

- Oscillating Wash Manifold to Maximize Cleaning

- Easy to Service Front Wash Pump Suction Strainer

- Adjustable Electronic Temp Control, Temp Gauge

- Control Transformer External of Panel minimizes Heat

- Programmable 24 Hour 7 Day Clock

- Low Water Shut-off Protects Pumps & Heating System

- Electronic Door Safety Interlock

- Wash Cycle Timer with Auto Reset

- Heavy gauge 3/16" Sheet Steel Cabinet Thickness

- 230 V or 460 V - 60 Hz 3-Phase with 120 V Controls

- Chemical Resistant Two Part 3 mil Epoxy Coating

| Work Area Dimensions: | US | Metric |

| Turntable Diameter: | 60 inches | 1520 mm |

| Work Height: | 75 inches | 1900 mm |

|

Table Load Capacity: |

3000 lbs | 1360 kg |

| Heavy Duty Capacity: | 7000 lbs | 3170 kg |

| Overall Dimensions: | US | Metric |

| Width: (Std Unit) | 106 inches | 2690 mm |

| Depth: (Std Unit) | 91 inches | 2310 mm |

| Height: | 120 inches | 3040 mm |

| Empty Weight: | 6850 lbs | 3100 kg |

| Reservoir Capacity: | 350 gallons | 1325 liters |

| Duplex Reservoir: | Add 47 gallons | Add 178 liters |

| Sludge Capacity: | 80 gallons | 303 liters |

| Spray Blast Manifold: | |

| OSCILLATING NON-SYNCHRONOUS Video | |

| Angle of Oscillation: (Picture) | 39 Degrees |

| Frequency of Oscillation: | 4 per minute |

| Number of Wash Nozzles: (Picture) | 24 |

| Type of Nozzle: | V-Jet |

| Nozzle Material: | 316 Stainless |

| Heating System: | US | Metric |

| Operating Temperature: | 140-190 degrees F | 60-88 degrees C |

| Initial Heat up Time: | 45-120 minutes | 45-120 minutes |

| Electric Heat Element Size: (Picture)** | 60 kW | 60 kw |

| Gas / Propane (Picture) | 400,000 BTU/hr | 117 kW |

| Electrical Panel (Picture) | US | Metric |

| Motor Starters: | Across the Line | IEC Type 2 |

| Short Circuit Protection: | Std | Coordinated |

| Overload Protection: | Std | Thermal Class 10 |

| Electrical Enclosures: | NEMA 12 | IP65 |

| Wiring Standard: | NFPA 79 | NFPA 79 |

| Wiring Conduit: | Flex-Non-Metallic | Flex-Non-Metallic |

| Conduit Type: | Liquidtight NEMA 12 | Liquidtight IP65 |

| Pump System & Performance: | |

| Motor Type: (Picture) | NEMA MG-1 |

| Motor Rating: | Continuous Duty |

| Motor Enclosures: | TEFC/NEMA 12 |

High Efficiency, Rated for continuous duty (20 Start/hour without overheating), vertical, centrifugal, seal-less, balanced, enclosed impeller. Note: All performance data taken at nozzle discharge.

| Standard: | 30 hp (US) | 22 kW (Metric) |

| Total System Flow: | 343 gpm | 1300 l/min |

| Flow per Nozzle: | 14.3 gpm | 54 l/min |

| System Pressure: | 121 psi | 8.3 bar |

| Blast Velocity: | 133 ft/sec | 41 m/sec |

| Power Density: | 0.25 hp/ft³ | 6 kW/m³ |

| UPGRADES: (DUPLEX) | 55 hp (US) | 41 kW (Metric) | 70 hp (US) | 52 kW (Metric) |

| Total System Flow: | 399 gpm | 1510 l/min | 431 gpm | 1630 l/min |

| Flow per Nozzle: | 16.6 gpm | 63 /min | 18 gpm | 68 l/min |

| System Pressure: | 163 psi | 11.2 bar | 190 psi | 13.1 bar |

| Blast Velocity: | 155 ft/sec | 47 m/sec | 168 ft/sec | 51 m/sec |

| Power Density: | 0.57 hp/ft³ | 11 kW/m³ | 0.76 hp/ft³ | 11 kW/m³ |

Results may vary based on machine configuration.

** Heating element sizes listed for 208, 240 & 480 volt systems. Sizes vary slightly for other voltages.